ABOUT WELD-ON

Weld-On is a globally recognized leader in the development and manufacturing of high-performance solvent cements, primers, and adhesives for PVC, CPVC, and other thermoplastic piping systems. With decades of industry expertise, Weld-On has earned a reputation for delivering innovative and reliable bonding solutions that meet the highest standards of quality, safety, and environmental responsibility.

Committed to sustainability, Weld-On offers low-VOC and environmentally friendly adhesive solutions without compromising performance. Their products are trusted by professionals across plumbing, industrial, irrigation, and construction sectors for their superior strength, ease of application, and long-term durability.

As a valued partner, Weld-On continues to set the industry standard, providing cutting-edge solutions that enhance efficiency and reliability in piping applications worldwide.

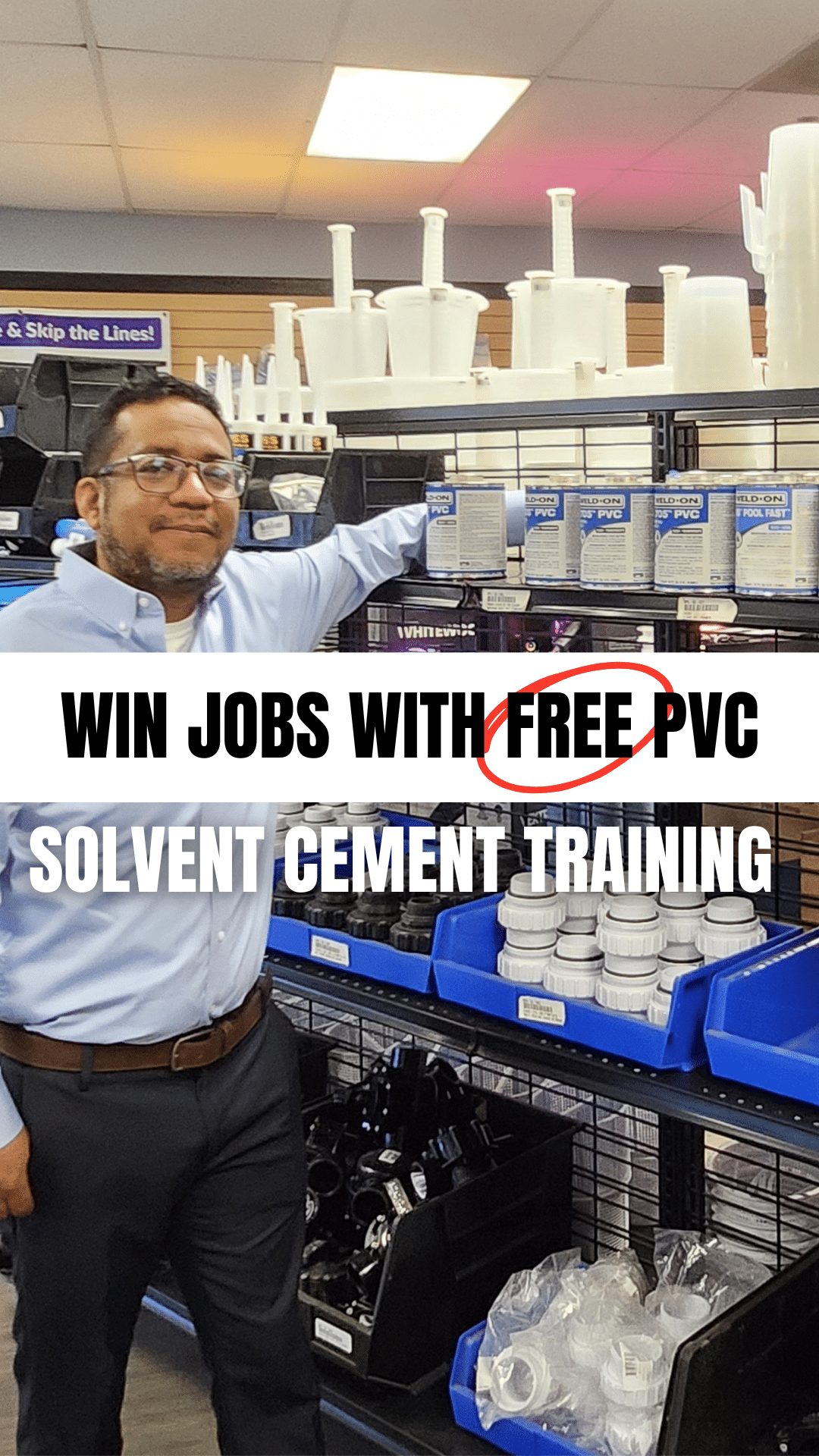

FREE technical training available

Weld-On’s solvent welding course is your secret weapon to leak-free joints, fewer callbacks, substantial savings, and the ability to choose the best cement for every application!

Why Take Weld On’s Course

- Learn tried-and-true techniques to safeguard your plastic pipe and joint projects

- Bid and execute confidently with reduced repair expenses

- Deliver leak-free projects for happy, loyal customers

- Complete projects faster with fewer callbacks

- Know how to select the ideal cement for each application, ensuring longevity and strength

- Benefit from expert guidance and hands-on training provided by industry leaders in solvent welding who have trained over 30,000 professionals.

- There are increasing numbers of contracts specifying that bonders be qualified to the ASME B31.3 standard. Qualification may lead to a decrease in incidents and reduced liability insurance premiums.

DESIGNED INTO 3 training MODULES

Seminar Module

Classroom Training

The basic principles of solvent welding pipe and fittings

Techniques per ASTM D2855 standard

How to choose the right solvent cement for the job

Causes of joint failure

Safety precautions

Field Practice Module

Hands on Training

Interference fit check between pipe and fitting

Pipe-end deburring

Primer application

Solvent cement application

Pipe joint assembly

Bonder Module

Qualification

Participant makes a pipe joint assembly

The assembled sample is hydrostatically pressure tested per ASME B31.3 bonder qualifications standards

If the sample passes the pressure test, a qualification card is issued to the participant*

small diameter pipe welding guide

english

English

Spanish

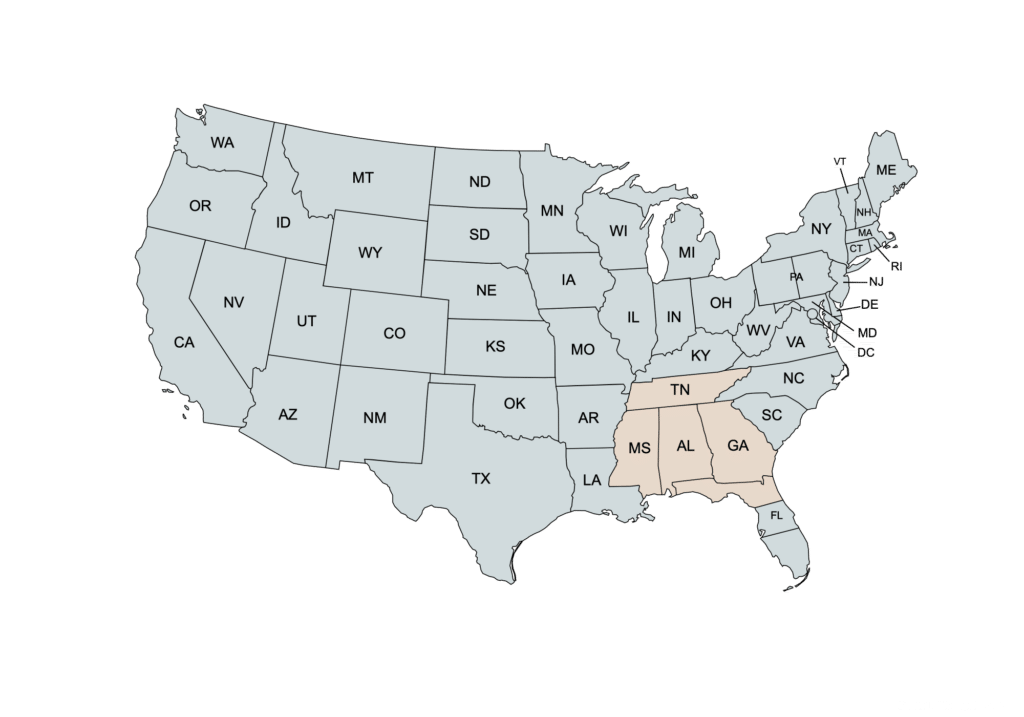

Find your local rep

Mississippi

Tennessee